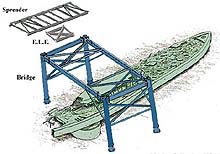

The engine recovery structure (ERS), made up of the bridge, spreader and engine lifting frame (ELF). Click image for larger view.

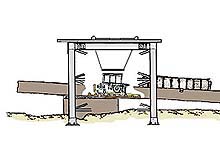

This cutaway drawing shows the Monitor’s engine attached to the ERS before the whole structure was raised. Click image for larger view.

Here, the ERS and engine are being lifted from the Monitor by the 500-ton crane on the derrick barge Wotan. Click image for larger view.

All illustrations courtesy of Jeff Johnston, NOAA, Monitor Collection.

How the Engine was Raised

July 17, 2001

Dr. John Broadwater, Manager

Monitor National Marine Sanctuary

Jeffrey Johnston, Historian

Monitor National Marine Sanctuary

The Monitor's engine could not be raised directly to the surface for two reasons: (1) because the engine is heavy, yet fragile, several weeks were required to properly rig it for recovery; and (2) connecting the engine directly to a cable on the surface would have subjected it to stresses caused by the sea motion of the barge and crane. Therefore, an Engine Recovery Structure (ERS) was placed over the Monitor's engine room to support the lift. The ERS consists of a bridge frame that spans the wreck, a moveable spreader, and an engine lifting frame (ELF) that is suspended from the spreader.

The spreader was moved until the ELF was suspended directly over the engine. Then, after the hull plating was removed, steel cables were connected between the engine and the ELF. Once the frame of the engine was supported in this manner, dozens of additional straps were added to ensure that all components of the engine (cylinder, piping, connecting rods, linkage and controls) would be supported for the lift. This process was lengthy, since the engine first had to be excavated from an encapsulating layer of corroded metal and coal.

Once rigging was complete, the entire engine unit was raised 2 ft using hydraulic rams mounted on the spreader. All rigging was inspected, and heavy-duty cargo nets were slung beneath the engine and secured to the ELF. The engine was then raised another 4 ft and reinspected. Everything appeared solid and secure.

After a final check on the weather, which was very good, steel lifting cables were attached to the ERS and the entire structure--an estimated 120 tons--was raised to the surface and placed on a waiting barge.

Sign up for the Ocean Explorer E-mail Update List.